Upon realizing the potential of digital biomanufacturing over traditional processes, players are actively undertaking initiatives to adopt advanced platforms to drive operational excellence, visibility, control and synchronization in bioprocessing.

Industry 4.0: An amalgamation of physical equipment and smart software

Digital biomanufacturing offers real-time process optimization based on factors, such as anticipated product quality and batch profitability. However, process optimization is one of the critical factors to be considered; both upstream and downstream processing must sustain the unique requirements of living cells and their products. Digital biomanufacturing software promotes asset availability and dependability, while minimizing the maintenance needs. Moreover, digital biomanufacturing significantly improves the ability to comprehend a full biomanufacturing process by coupling/linking physical processes with the digital domain.

At a glance

- 90% of the drug candidates fail, resulting in substantial financial losses [1]

- 70% of the data generated in biopharmaceutical sector is unstructured and unexploited [2]

- 25% gains can be achieved in manufacturing yield by substituting paper-based systems [3]

A surge in the biologic demand and burden associated with complex datasets has raised the need for solutions that create an end-to-end process in which all the functions are digitally enabled and connected to optimize the bioprocessing.

COVID-19 Fallout: An Inflection Point for Digital Bioprocessing

Since the outbreak of COVID-19, there has been an immense pressure on biopharmaceutical industry to reduce the production timelines and increase the speed and capacity of manufacturing, without compromising on the final product quality. Further, a surge in morbidity across the globe and enhanced interconnectivity of equipment and technologies has led to an increased burden on manufacturing operations. Other factors that influence the market include higher competition, competitive pricing, inflation rate, technological advancements and evolving regulatory guidelines. These factors demanded a fundamental shift from conventional manufacturing operations, subsequently leading to the introduction of industry 4.0 technologies.

Technologies, such as PAT and MES, were introduced pre-2000; however, in the field of biomanufacturing, these technologies were recognized and acknowledged in 2004. Further, during the period 2011-2014, pharma industry started adopting and implementing technologies, such as big data, AI, machine learning and IoT. During the same period, some companies launched their proprietary platforms for biomanufacturing; for instance, Siemens launched SIMATIC SIPAT V3.0 in 2010, Biopharma Services launched BioSolve Process and CellPort launched CellPort software to digitize the cell manufacturing in 2014.

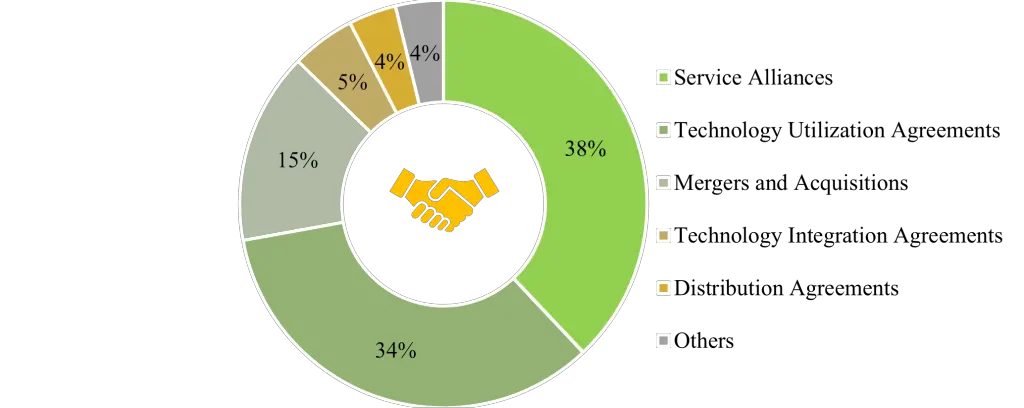

Fostering Partnerships: A key determinant in paving the way for industry maturation

With over 75 deals inked in the last few years, there has been a considerable increase in the consolidation activity within this domain; in fact, more than 60% deals were forged in last two years, indicating the growing interest towards digital manufacturing. Majority of the partnerships, inked in 2022, were technology utilization agreements, service alliances, and mergers and acquisitions. For instance, in October 2022, AspenTech acquired inmation Software with an aim to strengthen its technology portfolio and offer its customers an unrivalled enterprise-wide data infrastructure.

Given the inclination towards cutting-edge technologies, along with innovative approaches to tailor bioprocessing, we believe that the digital biomanufacturing technologies market is likely to evolve at a rapid pace in the coming years. We’ve also done a detailed market research report on digital biomanufacturing. You can click here to look at the detailed report on digital biomanufacturing.

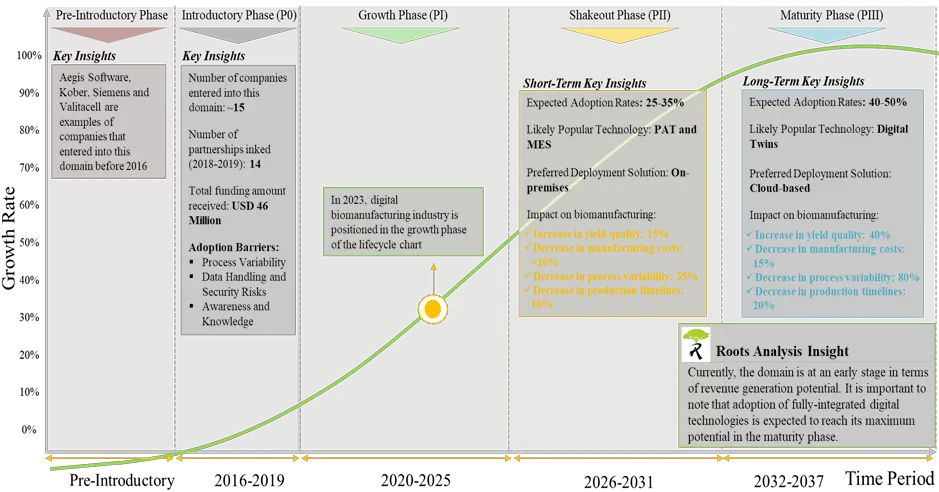

Industry Lifecycle Analysis: In 2023, digital biomanufacturing is positioned in the growth phase of the lifecycle chart

The industry lifecycle analysis illustrates the current position / phase of digital biomanufacturing industry on the lifecycle chart; it helps stakeholders make better decisions regarding the likely evolution and direction the industry might be heading towards. Based on the elements, such as historical trends, partnership activity, investments, key challenges, short-term and long-term outlook, we were able to map the digital biomanufacturing industry on the lifecycle chart comprising of various phases, including pre-introductory, introductory phase (P0), growth phase (PI), shakeout phase (PII) and maturity phase (PIII).

In the long-term, digital twins and cloud-based technologies are expected to witness substantial adoption. These fundamental advancements in the field of smart biomanufacturing are anticipated to promote process robustness and product quality, which will inevitably culminate in accelerated growth of the market.

References:

- 90% of drugs fail clinical trials – here’s one way researchers can select better drug candidates, 2022

https://theconversation.com/90-of-drugs-fail-clinical-trials-heres-one-way-researchers-can-select-better-drug-candidates-174152

- How digital solutions are transforming biomanufacturing, 2022?

https://www.labiotech.eu/partner/digitalization-transforming-biomanufacturing/

- An Introduction To Manufacturing Execution Systems For The Medical Device Industry, 2016

https://www.meddeviceonline.com/doc/an-introduction-to-manufacturing-execution-systems-for-the-medical-device-industry-0001

The post Next Generation Biomanufacturing – The Upcoming Era of Digital Transformation appeared first on Blog.