Dire Need for Automated Tool and Technologies (example Manufacturing Execution Systems) in Healthcare Manufacturing

The continuously growing demand for healthcare products and present economic environment drives the need for adoption of automated tool and technologies in order to improve manufacturing, process, increase throughput reduce cycle time, maintain quality and to get the best out of the available resources to eliminate unnecessary production costs. It is worth mentioning that in recent years, several healthcare stakeholders have actively undertaken initiatives to incorporate a manufacturing execution system (MES) into their production lines, with an aim to connect, monitor and control the complex manufacturing process. In addition, players are integrating advanced technologies, including internet of thing (IoT) and artificial intelligence (AI), in order to collect and analyse large volume of data from various sources, as well as to produce value in the form of insights, predictions and actions. Integrating advance tools and technologies with manufacturing execution system (MES) ensure smooth communication within different production process, enhance decision making capability of MES and also enhance risk prediction capabilities. We have proposed a proprietary framework in order to identify different tools and technologies which can be integrated with manufacturing execution system in order to increase it efficacy at different stages of production.

Value creation framework includes an insightful depiction for implementation of several advanced tools and technologies, such as artificial intelligence, cloud computing, internet of things (IoT) and machine learning at different stages of a production process, such as data storage, performance / data analysis, document control and process tracking which can assist MES providers to address unmet needs associated MES in healthcare domain. Additionally, it provides a detailed analysis on ease of implementation, associated risk and value creation in integrating such tools / technologies, based on the trends highlighted in published literature and patents. Below, I have pasted figure that depicts our proprietary framework.

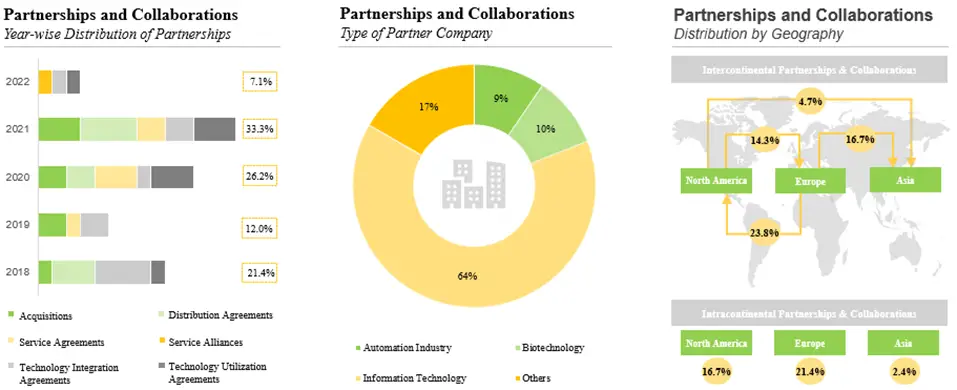

Recent Activity in Partnerships and Collaborations

Manufacturing execution systems is a technically complex and financially demanding solution; as a result, healthcare stakeholders prefer to rely on speciality service providers that claim to have the required expertise. Over the years, players offering MES have actively collaborated with stakeholders from across the globe in order to ink various agreements in this domain. Among these agreements, technology integration agreement emerged as the most popular (24%) type of partnership. The industry has also witnessed over five acquisitions in the given time period. This trend reflects the fact that companies are continuously striving to expand their existing offerings. Below, I have pasted figure that depicts key partnership trends along with some recent examples of agreements in this domain.

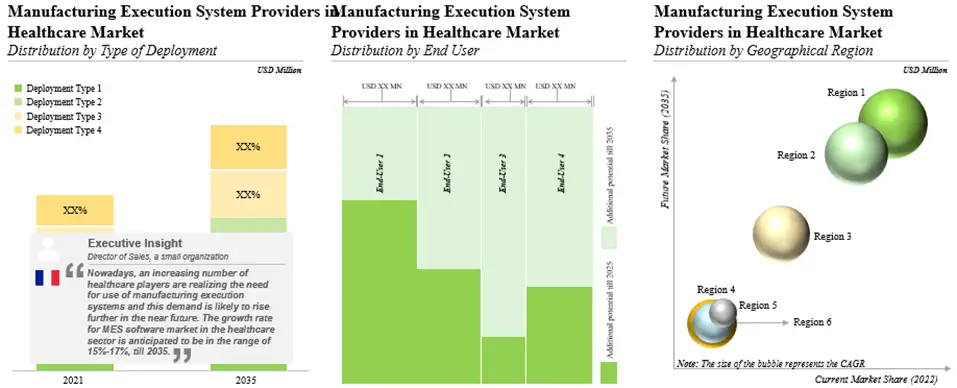

Manufacturing Execution System Providers in Healthcare Market is Anticipated to Grow at Over 16% CAGR

Driven by the increasing demand for MES solutions, market is projected to grow at a steady pace in the foreseen future. In addition, among It is worth mentioning that Europe presently has the maximum share in the growth of manufacturing execution system providers in healthcare market.

You can also download the SAMPLE REPORT on this topic by Roots Analysis by clicking on the link here

https://www.rootsanalysis.com/reports/manufacturing-execution-systems-market.html

The post Manufacturing Execution Systems: A Step Towards Smart Manufacturing in Healthcare Sector appeared first on Blog.